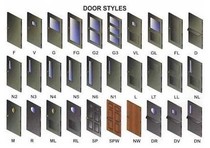

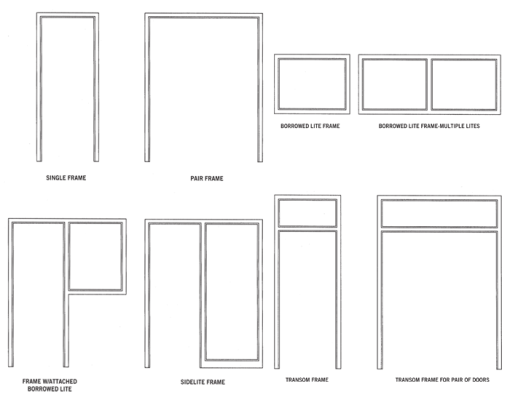

Different Frames:

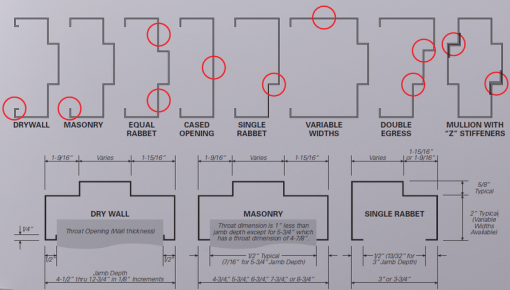

Masonry Frames (F-series)-

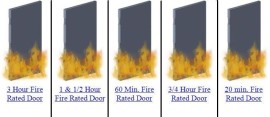

The standard F-series masonry frame is the best stock hollow metal assembly in the industry. In fact, we have proven our caliber for more than 145 years — a testament to our craftsmanship. We use

only the best materials, like 16 or 14 gauge cold rolled steel, or A60 Galvannealed steel for corrosive applications. State-of-the-art technology is employed for consistent and accurate quality, such

as our computer-controlled mig welders. Mesker surpasses the industry requirements by using 3/16 inch hinge reinforcements to outlast the heaviest doors. All our F-series frames are fire-rated 3 hour

and receive a embossed UL or Factory Mutual label.

Drywall Jamb Frames (FDJ-series)-

There is a major difference in our FDJ-series drywall frame when compared with other competitors. We use only 16 gauge cold-rolled or A60 Galvannealed steel, not the weaker gauges marketed by many

competitors. Our heavy gauge frames are designed to be pressure-fitted to the wall which improves unit life, and ensures durability with less torsion and sagging. Because we use heavier gauge steel

for our frame, stronger 3/16 inch hinge reinforcements can be welded to the rigid structure to hang heavier wood or metal doors.

Average installation time is 4-5 minutes per frame using our adjustable jamb lock for secure

anchoring. Additionally, two dimpled holes at the base of each jamb stabilize the frame during installation. All our FDJ-series frames are fire-rated 1-1/2 hour and receive a embossed UL or Factory

Mutual label.

Remodeling Frames-

Mesker remodeling units are ideal for any existing wall structure. Comprised of six individual components, they are formed from rigid, 16 or 14 gauge steel, and can be ordered in an array of profiles

and jamb depths. An individual header, hinge jamb, strike jamb, and the counterpart trim sections help the installer to make an adjustable, custom fit for each opening.

A welded-in,16-gauge floor anchor and eight countersunk, jamb holes for fastening to side walls hasten installation.

• Available Fire Rated up to 90 Minutes